Fiber Optic Test Equipment: The Cornerstone of Modern EMI/EMC Testing

In the ever-evolving landscape of EMI/EMC testing, precision and reliability are paramount. As electronic devices become more complex and interconnected, so too do the electromagnetic environments they operate in. To ensure these devices function safely and efficiently, rigorous testing is essential. Fiber optic test equipment has emerged as a cornerstone of modern EMI/EMC testing, offering solutions that address the unique challenges of high-interference environments.

Why Fiber Optics Matter in EMI Testing

The fundamental principle behind fiber optic technology – the transmission of data via light pulses – makes it uniquely suited for EMI/EMC testing. Let’s delve into the key benefits:

- Inherent EMI Immunity: Unlike traditional copper-based systems, fiber optic cables are immune to electromagnetic interference. This eliminates the risk of data corruption and signal distortion, ensuring accurate and reliable test results even in the presence of strong electromagnetic fields.

- Uncompromised Data Security: Light signals are inherently more secure than electrical signals, making fiber optic communication highly resistant to eavesdropping and data breaches. This is especially critical when testing sensitive or confidential electronic devices.

- Extended Range and Flexibility: Fiber optic cables can transmit data over significantly longer distances than copper cables without signal degradation. This allows for greater flexibility in test setup and configuration, particularly in large or complex testing environments.

- High Bandwidth and Data Throughput: Fiber optic technology supports high-bandwidth applications, enabling the efficient transfer of massive amounts of data generated during comprehensive EMI/EMC tests.

Fiber Optic Test Equipment: A Closer Look

The range of fiber optic test equipment available today is extensive, catering to the diverse needs of EMI/EMC testing labs. Here’s a glimpse into some essential components:

Fiber Optic Cameras:

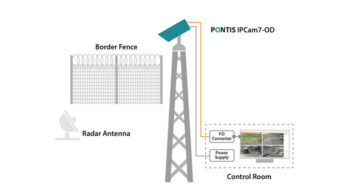

Capture high-resolution images and videos in EMI-rich environments with specialized shielded cameras. These cameras are indispensable for visual inspections and documentation during testing. Pontis EMC offers a variety of EMI-shielded cameras, such as the IPCam7 HD, Cam5 Compact, and HDCam5/HDCam6ECP. Learn more about the benefits of fiber optic cameras in our dedicated blog post: Fiber Optic Cameras for EMI/EMC Testing

Fiber Optic Converters:

Seamlessly bridges the gap between fiber optic and copper-based systems, ensuring compatibility and facilitating data transfer between different equipment types. Pontis EMC offers a variety of fiber optic converters, including foBROADR-REACH (Automotive), foCAN, foCARCHARGER, and foETHERNET. You can explore our full range of converters in our blog post: Fiber Optic Converters: Ensuring Signal Integrity in EMI Testing.

Shielded Audio Equipment:

Maintain clear and reliable audio communication during EMI/EMC testing with shielded audio equipment. Pontis EMC offers a selection of shielded audio solutions.

Video & Audio Systems for EMI Testing:

Seamlessly capture and analyze video and audio data with our specialized systems designed for EMI/EMC testing. Discover our Video & Audio Systems.

Other EMI/EMC Testing Equipment:

Explore our full range of EMI/EMC testing equipment, including amplifiers, antennas, generators, and more. Visit our Products page for details.

Pontis EMC: Your Partner in EMI/EMC Testing

At Pontis EMC, we offer a comprehensive portfolio of fiber optic test equipment designed to meet the rigorous demands of EMI/EMC testing. We understand that every testing environment is unique, so our team of experts is dedicated to helping you select the right tools and configurations for your specific needs.